In the previous section we have discussed about the magnetic field caused by earth and about the terms/corrections we take into account while using magnetic tools for various measurements. These measurements are sometimes subjected to magnetic interference and every care must be taken to avoid this so as to avoid wrong readings.

What is Magnetic Interference?

Magnetic interference can be defined as the corruption of geomagnetic field by a field from an external source. It can cause disruption in obtaining proper survey readings mainly azimuth; from the magnetic sensors.

Potential causes of magnetic interference may be due to:

- Drill strings/BHA

- Imperfections in non-magnetic drill collars (Hot Spots)

- Magnetic formations

- Casing & Adjacent wells

- At shallow depth, the platform itself

- Solar Wind

Among many error sources, drill string interference is one of the prime reason for the cause of errors in hole direction.

*Magnetic Interference from Drill Strings

The only way to ensure that a tool is not influenced by magnetic forces (other than the earth’s magnetic field) is to get the tool away from those forces. Magnetic force is inversely proportional to the square of the distance from the magnetic material.

For instance, if the total magnetic field is 10,000 gamma at 2", it will be 2500 gamma at 4" and 625 gamma at 8".

To prevent the drill string interference, we run our magnetic sensors within Non Magnetic Drill Collars (NMDC).

Non-magnetic spacing is very important when planning the BHA to remove the potential of magnetic interference. The drill string and its steel components are similar to the bar magnet. Each steel component, if separated by a non-magnetic component of sufficient length, will have its own north and south poles and will not link magnetic fields with other steel components as shown in the fig.

Hole Angle

Hole Angle

Magnetic interference from drill string increases with increasing inclination. This happens because horizontal component of drill string becomes larger percentage of magnetic field influencing magnetic measurement. Total field strength does not change and remains the same.

Thus, drill string interference is more in horizontal drilling.

Hole Direction

Drilling North-South reduces whereas, drilling East-West increases magnetic interference from the drill string.

In order to understand this, remember that the magnetic inclination near the equator is around one degree. Due east or west is approximately parallel to the horizontal component of the earth’s magnetic field, while due north or south is almost perpendicular to the horizontal component.

Because the east / west direction is roughly parallel to the horizontal component, the influence of the field pulling in the direction of Magnetic North is greatly reduced. As the horizontal component of the magnetic field decreases in strength, magnetic force from the BHA becomes a larger portion of the total magnetic field strength.

Drilling at high angles along the east / west line produces a greater likelihood of interference from the BHA as the horizontal component of the drill string’s magnetic field is a greater proportion of the total magnetic field.

Latitude

Moving closer to Magnetic North reduces the contribution from the horizontal component of the earth’s total magnetic field. Any reduction of the earth’s magnetic influence equals greater influence from the magnetic field of the drill string.

At higher latitudes, both north and south, more non-magnetic spacing is required to reduce interference from the drill string.

Hot spots

Non-Magnetic Drill Collars and other steel components may develop local areas where the magnetic field strength is greater than normal. These are called 'Hot Spots' in the component. Any component that has a hot spot creates greater magnetic interference than expected. It may be possibly due to bending or any other stresses. Before running NMDC in the hole, Hot Spots can be found by running a compass along the outside of the collar or pulling the compass through the inside by a string. If a hot spot is present, the needle will swing, indicating magnetism. The same NMDC shouldn't by run with the MWD tool. As the mud is circulated, it creates a small magnetic field across steel components. The hot spot may be further intensified by this action.

*Formation Constituents

Formations with massive iron-bearing formation may cause interference with magnetic measurements.

*Steel components left in hole or Casings

Any metal parts left in hole is called as 'fish'. It is a sure source of magnetic interference. Ensure that the current well bore is far enough from the fish to prevent magnetic interference.

At certain intervals during the drilling process, casing is set. Casing, comprised of steel tubes threaded together, keeps the hole stable. Since the drill string passes through the set casing, the magnetometers must be drilled far enough beyond the casing to ensure that surveys are not influenced by magnetic interference.

Well must also be drilled at a suitable distance from a cased well, so as to avoid interference.

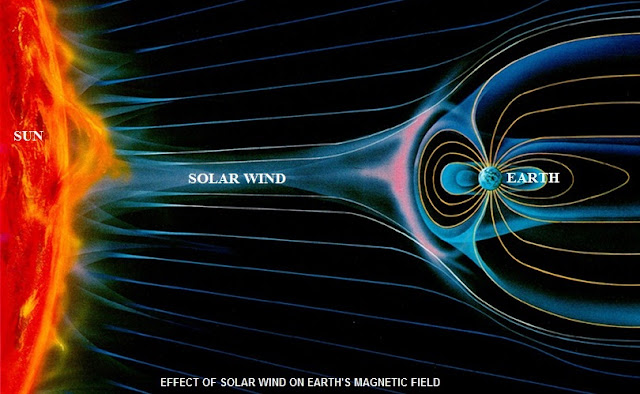

*Magnetic Interference from Solar Wind

About ninety percent of the earth’s total magnetic field is generated internally and approximately ten percent is contributed by solar wind sweeping over the earth’s magnetosphere. Severe changes in the solar activity may affect azimuth readings. Magnetic storms created by solar flares may be intense enough to interfere with magnetic readings on earth.

Some of the solar activity occurs on a cyclical basis and is not intense enough to create problems. However, random solar flares have the potential to generate magnetic interference. Most companies that provide M/LWD service issue warnings if solar activity is causing problems.

Practical Consequences

In practical terms, this means that the azimuth error due to drill string magnetic error increases with:

• Increased inclination

• More westerly or easterly direction of the borehole

• Higher Latitudes

• Insufficient magnetic spacing

The maximum error exists when the drill string is oriented east or west with 90° of inclination.

No azimuth error occurs when the drill string is oriented towards Magnetic North or when it is near vertical.

So. basically there are two problems.

Latitude

Moving closer to Magnetic North reduces the contribution from the horizontal component of the earth’s total magnetic field. Any reduction of the earth’s magnetic influence equals greater influence from the magnetic field of the drill string.

At higher latitudes, both north and south, more non-magnetic spacing is required to reduce interference from the drill string.

Hot spots

Non-Magnetic Drill Collars and other steel components may develop local areas where the magnetic field strength is greater than normal. These are called 'Hot Spots' in the component. Any component that has a hot spot creates greater magnetic interference than expected. It may be possibly due to bending or any other stresses. Before running NMDC in the hole, Hot Spots can be found by running a compass along the outside of the collar or pulling the compass through the inside by a string. If a hot spot is present, the needle will swing, indicating magnetism. The same NMDC shouldn't by run with the MWD tool. As the mud is circulated, it creates a small magnetic field across steel components. The hot spot may be further intensified by this action.

*Formation Constituents

Formations with massive iron-bearing formation may cause interference with magnetic measurements.

*Steel components left in hole or Casings

Any metal parts left in hole is called as 'fish'. It is a sure source of magnetic interference. Ensure that the current well bore is far enough from the fish to prevent magnetic interference.

At certain intervals during the drilling process, casing is set. Casing, comprised of steel tubes threaded together, keeps the hole stable. Since the drill string passes through the set casing, the magnetometers must be drilled far enough beyond the casing to ensure that surveys are not influenced by magnetic interference.

Well must also be drilled at a suitable distance from a cased well, so as to avoid interference.

*Magnetic Interference from Solar Wind

About ninety percent of the earth’s total magnetic field is generated internally and approximately ten percent is contributed by solar wind sweeping over the earth’s magnetosphere. Severe changes in the solar activity may affect azimuth readings. Magnetic storms created by solar flares may be intense enough to interfere with magnetic readings on earth.

Some of the solar activity occurs on a cyclical basis and is not intense enough to create problems. However, random solar flares have the potential to generate magnetic interference. Most companies that provide M/LWD service issue warnings if solar activity is causing problems.

Practical Consequences

In practical terms, this means that the azimuth error due to drill string magnetic error increases with:

• Increased inclination

• More westerly or easterly direction of the borehole

• Higher Latitudes

• Insufficient magnetic spacing

The maximum error exists when the drill string is oriented east or west with 90° of inclination.

No azimuth error occurs when the drill string is oriented towards Magnetic North or when it is near vertical.

So. basically there are two problems.

- How many NMDC are required in the BHA?

- Positioning of the sensors within the nonmagnetic section?

The number of NMDC required depends on various factors:

- the horizontal component of the earth's magnetic field,

- the inclination and the azimuth of the well.

The size of the horizontal component of the earth's magnetic field depends on the total field strength and the dip angle, which in turn depends on the geographical location. Hence, the number of NMDC required on a well with a given inclination and azimuth varies considerably according to position on the earth's surface.

Rules of Thumb for Magnetic Sensor Spacing

The spacing of the magnetic sensor is given as a percentage of the total length of NMDC in the BHA.

Spacing is the height of the compass above the bottom of the entire NMDC section.

1. Consider how much steel there is below the NMDC.

Less than a 9"section is considered minimum;

9 to 20" is the intermediate case;

greater than 20" is maximum, in particular if a downhole motor is being used.

If minimum steel is used below NMDC ......spacing at 33% approx.

If intermediate is used below NMDC ..........spacing at 40% to 45%

If maximum steel is used below NMDC .....spacing at 45% to 50%.

2. Do not position the magnetometers within 3" of any tool joint.

3. Do not position the magnetometers within 5" of a non-magnetic stabilizer.

You actually make it seem so easy with your presentation but I find this matter to be actually something thatt I think I wohld never understand.

ReplyDeleteIt seems too complex and extremely broad for me.

I am looking forward for your next post, I'll try to

get the hang of it!

give it a few more reading... i'm sure you'll understand it further.

Deletethanks

Good article. I am going through a few of these issues as well..

ReplyDelete